The Basics of Weld and Safety in Every Welder's Day

- Mick Delaney

- Aug 8, 2025

- 7 min read

Ever started a shift thinking, "I'll sort that later"—whether it's tightening a gas bottle chain, swapping a dodgy helmet lens, or clearing that tangle of leads? Most of the time, you get away with it… until the one day you don't.

We've all been there. The morning rush, the pressure to get cracking, the familiar workspace that feels safe because you've navigated it a thousand times before. But here's the thing that might surprise you: WHS data shows over 60% of welding-related incidents in Australia trace back to small safety habits slipping—not big disasters, not equipment failures, but the little things we tell ourselves we'll fix "next time."

This isn't a lecture about weld and safety protocols you already know by heart. It's a reality check for experienced welders who want to keep the basics alive and keep everyone—including themselves—safe on the job. Because after 20 years in Aussie workshops, I've seen how quickly the fundamentals can fade when routine takes over.

The Basics That Fade First

When Good Habits Go Quiet

The irony of being experienced is that the very competence that keeps you safe can also make you complacent. It's not that you've forgotten safety procedures—you could recite them in your sleep. It's that familiarity breeds assumption, and assumptions create blind spots.

PPE checks becoming "assumed": are probably the biggest culprit. That helmet you've worn for two years? You know it works, so you stop checking if the lens is getting scratched or if the headband's fraying. Those gloves that fit like a second skin? They're comfortable, so you don't notice when the leather starts wearing thin near the thumb. Your respirator feels fine, so you assume the filters are still doing their job—until you realise you haven't changed them in six months.

Gas cylinder securement: is another area where standards slip, especially when workshop space gets tight. New blokes get the full safety briefing about chaining bottles, but veteran welders start thinking, "I'll just lean it here for five minutes" or "It's only moving two metres." The chains become suggestions rather than requirements.

Ventilation systems: present their own challenges. You switch off the extraction fan to clean around it or move equipment, then get straight into the next job without switching it back on. An hour later, you're wondering why your eyes are stinging, but the fan's become background noise—when it's not running, you don't immediately notice its absence.

Why do these habits fade? Three reasons that every long-term welder recognises: routine makes us overconfident, speed pressures make us skip steps, and "it's always been fine" thinking makes us believe past luck guarantees future safety.

The 'Small Stuff' That Triggers Big Fines

When Minor Becomes Major in WHS Eyes

Here's where experienced welders often get caught off guard. You know the big safety rules—proper ventilation, correct PPE, safe gas handling. But WHS inspectors and safety audits don't just look at the obvious stuff. They dig into details that busy workshops sometimes overlook.

Expired test tags on machines: are classic gotchas. Your welding set works perfectly, passes every practical test you can think of, but if that little tag says it was due for testing three months ago, you're non-compliant. Same goes for extension leads, grinders, and any other electrical equipment in the workshop.

Safety signs: cause more violations than you'd expect. That fire exit sign that's faded from years of welding light exposure? Non-compliant. The gas cylinder storage sign that got torn and nobody replaced? Non-compliant. Wrong signage for your specific hazards? You guessed it.

Fire extinguishers: are another frequent catch. They might be right where they should be, fully charged and ready to go, but if they're blocked by materials, overdue for service, or the wrong class for welding fires, inspectors will flag them immediately.

I've seen audits where 70% of non-compliances were things the boss considered "minor"—paperwork, signage, test tags—but the fines were anything but minor. A Queensland fabrication shop copped $15,000 in penalties for issues that took less than two days to fix, simply because they'd been putting off the administrative side of safety compliance.

Workshop Habits Worth Re-Checking

Five-Minute Fixes for Major Safety Gains

The beauty of addressing fundamental safety practices is that most improvements take more time to think about than to actually do. Here are the quick wins that experienced welders can build into their existing routines without disrupting workflow.

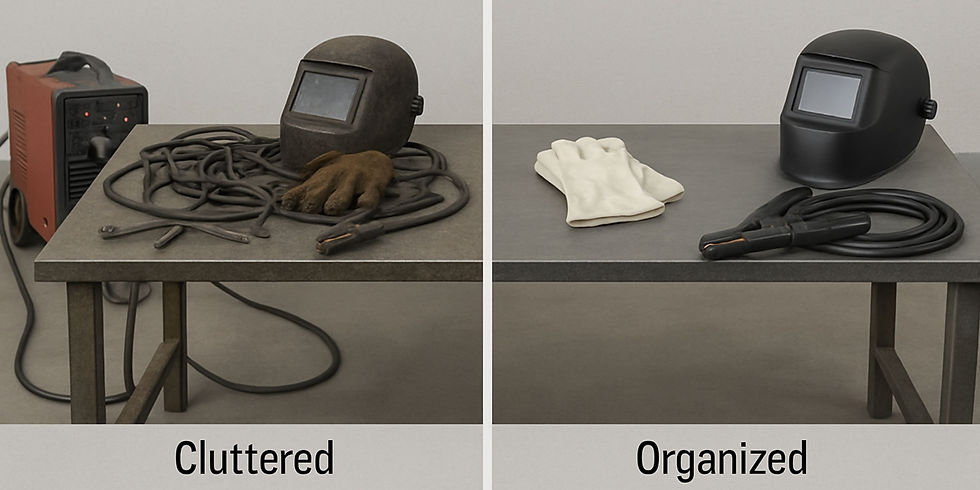

One-minute gear check before starting: becomes automatic once you establish the pattern. Helmet lens clear? Gloves intact? Leads untangled and insulation sound? Gas connections tight? It's not about being paranoid—it's about catching problems before they catch you.

Daily walk-around: of your workspace takes less time than making a coffee, but spots issues while they're still easy fixes. Look for gas leaks (that soapy water trick never gets old), blocked exits (amazing how quickly materials accumulate), and trip hazards (those leads have a life of their own). The key is making this a habit rather than an occasional check.

Weekly tag check: on tools and welding machines keeps you ahead of expiry dates. Most blokes check their equipment's performance constantly—you know immediately if your welder's playing up or your grinder's getting rough. Checking the compliance tags just extends that same attention to the administrative side.

PPE rotation every quarter: prevents the gradual degradation that's hard to notice day-to-day. Your welding safety Personal Protective Equipment deteriorates slowly, like the way you don't notice a mate ageing until you see an old photo. Setting a calendar reminder to assess and replace worn gear keeps your protection fresh.

Building a Culture That Catches Misses

Making Safety Checks Automatic, Not Additional

The difference between workshops that maintain high safety standards and those that slide into complacency often comes down to culture rather than individual discipline. It's about building systems where safety checks become part of the job-starting process, not an add-on that competes with productivity.

Integration beats addition every time. Instead of creating separate safety routines, embed checks into existing workflows. When you're setting up your welding station, checking gas flow and connection integrity becomes part of the setup, not a separate task. When you're positioning materials, clearing your workspace, and checking ventilation happens naturally.

Quiet peer checks work better than formal buddy systems in most Aussie workshops. It's not about officially monitoring each other—it's about mates naturally watching out for problems. "Your helmet strap's looking rough, mate," or "Did you mean to leave that bottle unchained?" These casual observations prevent incidents without creating a policing atmosphere.

A comprehensive welding safety checklist can support this culture by providing clear, actionable items that teams can work through together. When everyone knows what to look for, problems get spotted faster.

Digital logbooks help track what's been done and what's been missed without creating paperwork burdens. Simple smartphone apps or shared spreadsheets let everyone see maintenance schedules, safety checks, and equipment status. When the afternoon shift can see that the morning shift noted a "slight gas leak on Bay 2," problems get addressed instead of ignored.

Why It Matters Beyond Compliance

The Real-World Benefits of Getting Basics Right

Experienced welders know that safety isn't just about avoiding inspectors or preventing accidents—though both matter. Consistent attention to fundamental practices creates tangible benefits that improve daily work life and business outcomes.

Avoiding downtime from preventable incidents: keeps projects on schedule and maintains client relationships. A welding helmet with a cracked lens might seem like a minor issue until it causes arc eye, putting an experienced welder out of action for days. Gas leaks that could have been caught during daily checks can shut down entire work areas when they're finally discovered.

Higher productivity when gear's always ready: eliminates the frustrating delays that come from equipment problems mid-job. When your welding safety equipment is maintained consistently, you're not spending time troubleshooting preventable issues or hunting for replacement parts.

Building client and inspector confidence: in your workshop creates opportunities and reduces scrutiny. Clients notice well-maintained facilities and proper safety practices—it signals professionalism and reliability. Inspectors who see consistent compliance tend to focus their attention on workshops that show signs of cutting corners.

For many experienced welders, this systematic approach to safety fundamentals also reduces mental load. When you know your equipment is sound, your workspace is organised, and your procedures are current, you can focus entirely on the skilled work that defines professional welding.

The Five-Second Rule That Changes Everything

Here's something that'll stick with you: next time you're about to strike an arc, take five seconds. Just five. Look at your helmet, glance at your gas connections, check your workspace. That's it. Those five seconds aren't about following rules—they're about respect. Respect for the craft that's given you a career, respect for the mates working beside you, and respect for the families waiting for everyone to come home safe.

You've already built a safe, capable workshop through years of experience and dedication. The difference between workshops that maintain their edge and those that slide into complacency isn't knowledge—it's whether they keep these small fundamentals alive when routine tries to make them feel optional. Six months from now, when you're setting up for a job and you pause for that quick check, you'll remember this conversation. When a mate mentions a close call that could've been prevented, you'll think about these basics. When an inspector walks through and nods approvingly at what they see, you'll know why. The best welders aren't just skilled with a torch—they're the ones who make safety look effortless because they've made it automatic. They're the ones other welders watch and learn from, not because they follow every rule perfectly, but because they understand that the fundamentals never stop mattering.

That's the mark of a professional who's built something worth protecting. If you'd like a ready-to-use safety checklist tailored to your welding setup, we can help map one out that fits your specific workshop conditions and workflow requirements. Because getting the basics right isn't just about compliance—it's about keeping the standards that define quality Australian welding.

FAQs

What's the number one cause of welding safety breaches in Australia?

Inadequate PPE maintenance and checks, particularly worn or damaged equipment that's still being used. It's not usually about not having safety gear—it's about continuing to use gear that's past its effective life.

How often should welding PPE be checked or replaced?

Daily visual inspection before use, monthly detailed assessment, and replacement based on manufacturer guidelines or visible wear. Helmets typically last 2-3 years with regular use, gloves need replacing every 3-6 months depending on work intensity, and respirator filters should be changed monthly or when breathing becomes difficult.

Are small safety violations really fined in Aussie workshops?

Absolutely. SafeWork agencies regularly issue significant penalties for administrative non-compliance like expired tags, inadequate signage, or missing documentation. These "paperwork violations" can cost thousands of dollars even when no actual danger occurred.

Who's responsible for daily welding safety checks—workers or supervisors?

Both share responsibility under Australian WHS laws. Workers must take reasonable care for their own safety and follow welding safety procedures, while supervisors must ensure systems are in place and followed. The key is clear allocation of specific tasks to avoid assumptions.

What's the fastest way to spot a welding hazard before starting work?

A systematic 60-second scan: workspace clear, equipment tagged and functional, PPE intact, ventilation operating, gas connections secure, and emergency equipment accessible. Experienced welders can do this almost automatically once it becomes routine.

Comments