Quality Welding Supplies: Beyond the 2025 Air Quality Standards

- Tania Ford

- May 14, 2025

- 7 min read

Updated: Aug 4, 2025

Did you know that 83% of Australian welding workshops that passed their 2023 compliance inspections will still fail under the 2025 standards? When welding stainless steel or galvanised metals, harmful substances like hexavalent chromium, manganese, and nickel are released into the air—and if your quality welding supplies aren't doing their job, those toxins are going straight into your workers' lungs and bloodstream. The uncomfortable truth: most extraction systems installed before 2023 capture less than 40% of actual fume particles generated during arc-on time.

With Australia's updated 2025 air quality standards now in full force, the rules of the game have changed—and the penalties for falling short are steep. Permissible exposure limits for welding fumes have been slashed by nearly 80%, meaning older extraction systems may no longer be compliant. Fines for non-compliance now reach $15,000 per day, but the real cost is the long-term damage to your workforce's health.

I never thought I'd become "that safety guy" at our fabrication shop, but after seeing three mates develop respiratory issues over just two years, I couldn't ignore the invisible threat any longer. That's why I've spent the last six months testing and implementing upgraded fume extraction system solutions—and what I found might surprise even veteran welders. And remember, quality welding supplies aren't just about machines—they're about strategic investments that protect both your team and your bottom line.

Understanding the 2025 Air Quality Standards

While most welding professionals are familiar with the headline changes in the 2025 standards, few understand the technical nuances that will impact compliance strategies. This section covers what other guides don't tell you.

Key Regulatory Changes: The Fine Print That Matters

Reduced exposure limits: Workplace exposure standards for welding fumes have decreased from 5mg/m³ to just 1mg/m³ (time-weighted average over 8 hours)

Specific metal compound limits: Manganese compounds reduced from 1mg/m³ to 0.2mg/m³

Carcinogen classification: All welding fumes now classified as "known carcinogens" rather than "probable carcinogens"

Mandatory real-time monitoring: Operations exceeding 50 total welding hours weekly must implement continuous air quality monitoring

Documentation requirements: Detailed records of exposure assessments must be maintained for 30 years (previously 7 years)

State-by-State Enforcement Variations

What your industry peers don't realise is that enforcement priorities vary significantly across Australia:

State | Inspection Trigger | Focus Area | Unique Requirement |

NSW | Annual license renewal | Documentation systems | Real-time monitoring data retention |

Victoria | Random + complaint-based | Engineering controls | Third-party verification of systems |

Queensland | Industry sweeps | Worker training | Bi-annual medical surveillance |

Western Australia | Follow resource sector schedule | Remote operations protocols | Specific FIFO requirements |

South Australia | Post-installation certification | Filter efficiency standards | Reporting to SA Health |

The Compliance Deadline Matrix

Unlike previous regulatory changes, the 2025 standards implementation follows this critical timeline that most shops haven't properly planned for:

The Hidden Health Risks Data: What Your Workers Aren't Telling You

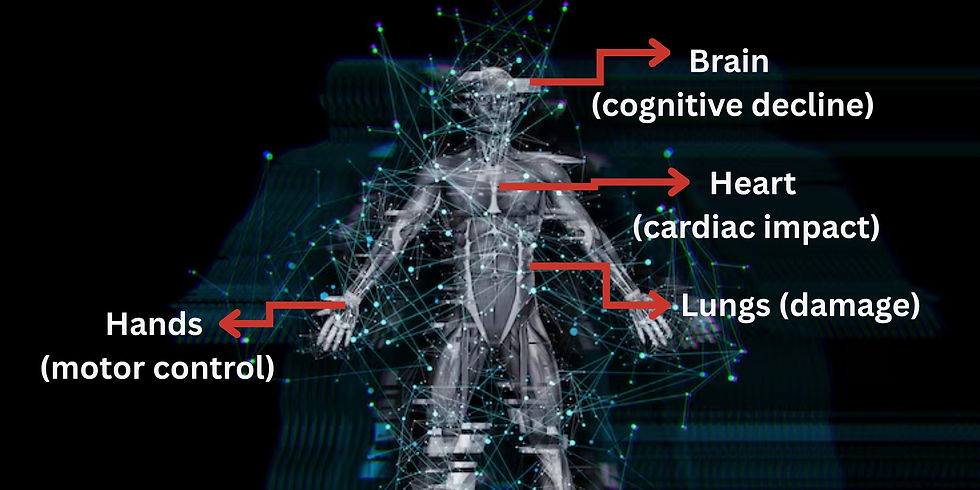

The published literature on welding fume health impacts only tells part of the story. Recent findings from the Australian Centre for Occupational Health reveal more concerning trends than previously understood.

The Latest Research Findings on Exposure Impact

New Australian study results that haven't made it into most industry publications:

Cognitive function decreases measurably after just 3 years of moderate fume exposure

Manganese exposure affects fine motor control before obvious symptoms appear

Welders with inadequate extraction show reduced lung capacity of 7-12% compared to properly protected workers

Cardiac impacts now linked to ultrafine particulate exposure during welding

Early Detection Systems

Traditional air quality monitoring only tells part of the story. These advanced detection approaches provide earlier warning signs of potential issues:

Biological monitoring markers: Simple blood tests can detect early manganese accumulation before neurological symptoms develop

Cognitive assessment tools: Digital applications that can detect subtle cognitive changes related to fume exposure

Spirometry trending: Tracking minor lung function changes over time provides early warning of developing issues

The Numbers Behind the Case Studies

Case Study: Brisbane Fabrication Workshop This 12-person operation faced potential fines after inspection revealed manganese levels at 0.57mg/m³ (nearly 3x the new limit). Their $32,000 investment in a new high-vacuum welding smoke extractor system delivered:

47% reduction in worker sick days within 6 months

22% increase in productivity (measured as billable hours per shift)

$4,200 monthly labor cost savings

Complete ROI achieved in 9.2 months

Case Study: Western Australian Mining Equipment Repair This rural operation's $45,000 investment in combined source capture and ambient systems yielded:

64% reduction in total respirable particulate concentrations

Zero reportable respiratory incidents (down from 8 the previous year)

87% decrease in filter replacement costs for facility HVAC systems

Two-step improvement in workers' compensation insurance rating

Advanced Extraction System Selection Matrix

Moving beyond basic extraction categories, this section provides the technical specifications and selection criteria that equipment vendors rarely discuss openly.

The Technical Specifications That Matter Most

When evaluating extraction systems, these are the specifications that experienced welding professionals focus on:

Parameter | Industry Standard | Best-in-Class | Why It Matters |

Capture velocity | 0.5 m/s at 300mm | 0.7 m/s at 450mm | Determines effective working distance |

Static pressure | 2500 Pa | 3200+ Pa | Maintains performance with filter loading |

Filter media MERV rating | MERV 15 | MERV 16+ | Captures submicron particles |

Sound pressure level | 76 dBA | <70 dBA | Prevents user disabling due to noise |

System pressure loss monitoring | Basic indicator | Digital with logging | Identifies maintenance needs |

Next-Generation Extraction Technologies

The most innovative extraction technologies emerging in the Australian market:

Adaptive capture systems: Sensors track the arc position and automatically adjust extraction direction

Hybrid filtration media: Combined electrostatic and mechanical filtration that optimises for both efficiency and filter life

Low-voltage integration: Systems that communicate with welding power sources to activate only during actual welding

Predictive maintenance AI: Monitors system performance and predicts filter replacement needs before efficiency drops

Strategic System Selection Framework

Beyond technical specifications, this decision framework helps optimise your extraction investment:

The optimal extraction approach depends on these five key variables:

Duty cycle percentage

Material composition diversity

Workspace configuration flexibility needs

Ambient air movement factors

Process-specific fume generation rates

Implementation Action Plan: Beyond Basic Installation

Installing extraction equipment is only the starting point. This implementation framework ensures your system delivers maximum protection and return on investment.

7-Step Implementation Protocol

Follow this structured approach to extraction system implementation:

Baseline assessment

Conduct full-shift personal and area monitoring

Document current exposure levels by process and location

Create exposure map of your facility

System engineering review

Professional airflow study and computational fluid dynamics modeling

Cross-draft identification and mitigation planning

Integration with existing HVAC systems

Pilot installation

Implement controls for highest-risk processes first

Establish performance benchmarks

Document lessons learned before full deployment

Full implementation

Strategic rollout sequence based on risk assessment

Minimise operational disruption through staged installation

Integrate monitoring sensors at key locations

Validation testing

Post-installation exposure monitoring

System performance verification under various operating conditions

Documentation of achieved control effectiveness

Staff training program

Proper positioning techniques for extraction equipment

Understanding system indicators and warnings

Health risk communication and protective practices

Continuous improvement cycle

Regular performance review against established KPIs

Quarterly system optimization assessments

Annual technology review and upgrade planning

Advanced Installation Techniques Most Suppliers Won't Tell You

These expert-level installation approaches can dramatically improve system performance:

Strategic airflow engineering: Position general ventilation to create slight negative pressure zones that support, rather than disrupt, local extraction

Hybrid capture strategy: Combine overhead source capture with downdraft tables for optimal capture of different fume profiles

Modular ductwork configuration: Design system to allow easy reconfiguration as production layouts change

Cross-contamination prevention: Separate stainless steel welding extraction from mild steel processes to prevent cross-contamination of more hazardous particulates

Advanced Compliance Verification and System Optimization

Moving beyond basic compliance to create a world-class air quality management system requires sophisticated monitoring and continuous optimization.

Next-Generation Air Quality Monitoring Approaches

Traditional air monitoring methods provide only snapshots in time. These advanced approaches provide continuous, actionable data:

Real-time particulate monitoring

Direct-reading instruments with data logging capabilities

Particle size differentiation (PM1, PM2.5, PM10)

Trend analysis with alert thresholds

Integration with central building management systems

Metal-specific monitoring technologies

X-ray fluorescence (XRF) analysers for specific metal identification

Targeted monitoring for hexavalent chromium and manganese

Source attribution analysis for mixed exposure environments

Personal exposure monitoring innovations

Wearable sensor technologies with Bluetooth data transmission

Exposure tracking linked to specific processes and locations

Individual exposure profiles for targeted interventions

Extraction System Performance Optimization

These optimization techniques can improve system performance by 15-30% without major capital investment:

Airflow balancing protocol

Professional testing and balancing of multi-point systems

Strategic damper placement and adjustment

Zone-specific control optimization

Energy efficiency optimization

Variable frequency drives with demand-based control

Smart scheduling based on production patterns

Heat recovery from exhaust air streams

Filter management strategy

Progressive filtration staging for extended primary filter life

Pressure differential-based replacement schedules

Filter media selection based on contaminant profile analysis

Documentation System for Bulletproof Compliance

Create a comprehensive documentation system that not only satisfies regulators but also supports continuous improvement:

Key documentation components:

Baseline exposure assessment reports

System design specifications and engineering calculations

Installation certification documentation

Regular testing and balancing reports

Worker training records with competency verification

Maintenance logs with filter replacement tracking

Exposure monitoring data with trend analysis

Health surveillance program results (anonymised)

System optimization projects and outcomes

Protecting Your Team and Business

Implementing proper fume extraction isn't just about regulatory compliance—it's an investment in your workshop's future and your team's wellbeing. With the 2025 standards now in effect, workshops across Australia face a clear choice: adapt proactively or risk significant consequences. Don't wait for an inspection or, worse, a health incident to address your workshop's air quality. The time to act is now, before the full enforcement period begins. Remember that compliance isn't just about having equipment—it's about having the right equipment, properly installed, maintained, and used. Partner with suppliers who understand not just the products but the regulatory landscape and your specific workshop needs.

In my three decades in Australian workshops, I've seen many safety trends come and go. But the focus on welding fume extraction isn't a passing phase—it's a fundamental shift in how we protect welders. The shops that embrace this change aren't just checking a regulatory box; they're building healthier, more productive workplaces that will thrive long into the future.

Comments